Rotating belt condensing granulator

SCF rotating belt condensing granulator

I. Operating principle of SCF rotating belt condensing granulator

Schematic Diagram for Rotating Belt Condensing Granulator

Structure Chart of Rotating Belt Condensing Granulator

The SCF rotating belt condensing granulator is of melt granulation process. It is used to distribute the hot melt material in the upstream process on the steel belt moving at a uniform speed under the machine through the distributing device of the machine and the continuous spray and cooling device is arranged under the steel belt to cool and solidify the material on the steel belt in the movement process to achieve the purpose of granulation.

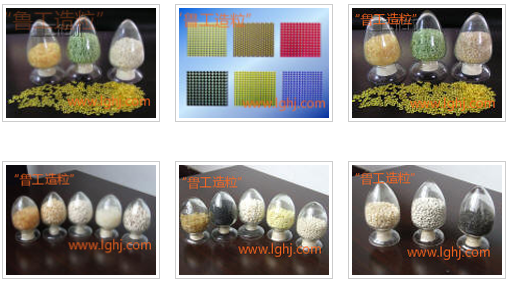

As for the rotating belt condensing granulator, the intermittent dripping, continuous discharge, full width overflow and other distributing forms can be chosen in terms of granulation form to produce hemispherical, strip and flake-like products.

II. Customer Drawing of SCF Rotating Belt Condensing Granulator and Corollary Equipment

III. Characteristics of SCF rotating belt condensing granulator

1. Manufacturing standards of military equipment: As for the design and manufacture of granulator, the company implements the same ISO9001 quality certification system as military equipment, and the equipment adapts to complex production conditions and customer quality requirements

2. Stainless steel strip: stainless steel strip selected by industrial granulation equipment, with hard and smooth surface, corrosion resistance, high and low temperature resistance, high thermal conductivity and easy maintenance, so that the hot melt material can be cured and formed. The company can produce different specifications of steel belts according to customer requirements, including the length, width, thickness and surface finish of steel belts;

3. Mature technology from Europe: the equipment runs smoothly, the noise is low, the continuous operation can be carried out, the productivity is high, the particle size is orderly, uniform and the particle size is small;

4. Energy saving and environmental protection in the production process: cooling water can be recycled, reduce dust, and increase the operating environment;

5. Uniform frequency speed regulation of the distributor and steel belt: the appropriate speed can be selected according to the nature of the material to facilitate adjustment and control;

6. Customer's evaluation of the company's after-sales service: no "satisfied", are "very satisfied"! The company (c682.cn) for lifetime maintenance of equipment!

Ⅳ. SCF type rotary belt condensing granulator application range

As a melt granulator, the product is suitable for melting point (softening point) within 250℃, need condensation granulation materials. Such as: paraffin, petroleum resin, C5 resin, C9 resin, C5C9 polymeric resin, alkali sulfide; Asphalt, maleic anhydride, stearic acid products; Hot melt adhesives, additives, rubber and plastic additives, antioxidants, antioxidants, light stabilizers 622/944 and other products.

Figure: Sample of pelletized products

Ⅴ. Main technical parameters of SCF type rotary belt condensing granulator

1. Production capacity: depends on the performance of specific materials.

2. Particle size: according to user requirements.

|

Model

|

Strip width(mm)

|

Productive capacity(Kg/h)

|

Steel belt/Distributor (Drive power Kw)

|

Overall length(m)

|

Reference weight(Kg)

|

|

SCF 600

|

600

|

100-400

|

1.5/2.2

|

18.2

|

1500~3000

|

|

SCF1000

|

1000

|

200-800

|

5.5/2.2

|

18.2

|

2700~6000

|

|

SCF1200

|

1200

|

300-1000

|

5.5/2.2

|

18.2

|

3000~7000

|

|

SCF1500

|

1500

|

500-1200

|

5.5/2.2

|

18.2

|

4000~9000

|